durometer hardness test theory|durometer hardness tester : manufacturer Surface Hardness Indicator. A durometer gage measures the depth of surface penetration for a pin of a predetermined geometry. The device is essentially a machine shop . CAD Converter - M4A Converter | CloudConvert

{plog:ftitle_list}

Resultado da 13 de jul. de 2022 · Slotmania.it offre agli utenti la possibilità di giocare alle slot gratis online senza scaricare nessun software, sfruttando dei player sviluppati in linguaggio HTML5. Molte delle slot gratis presenti sul nostro sito sono disponibili nella versione demo anche sui migliori casinò italiani con .

what is a durometer material

agile methodology and its impact on testing

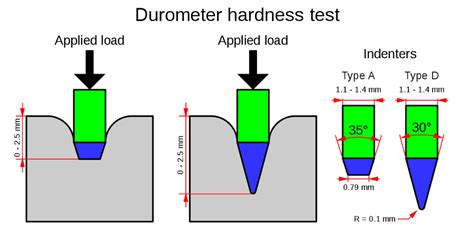

Surface Hardness Indicator. A durometer gage measures the depth of surface penetration for a pin of a predetermined geometry. The device is essentially a machine shop .Durometer Hardness is used to determine the relative hardness of soft materials, usually plastic or rubber. The test measures the penetration of a specified indentor into the material under . The ASTM D2240 standard outlines the test procedure for measuring the hardness of elastomers using a durometer. The test involves measuring the depth of penetration of a . The procedure for determining indentation hardness of substances classified as thermoplastic elastomers, vulcanized (thermoset) rubber, elastomeric materials, cellular .

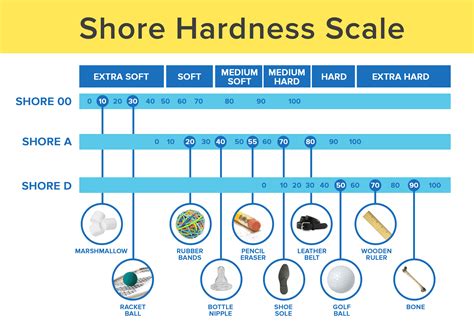

The Shore A hardness (durometer) scale is one of many durometer scales used to measure material hardness. Shore A durometers range from 0 to 100 — the higher the durometer value, the harder the material.

Shore Durometer hardness testing of plastics is described, and conversion charts correlating various scales are presented. The Shore Duromter A and D scales of hardness are commonly used for rubber and 'soft' polymers such as .Share. Hardness Shore D. What is Shore D hardness? Which tool measures Shore D hardness? What does the depth of penetration depend on? What factors affect the hardness of the . What is the Shore D Hardness Scale? The Shore D Hardness Scale is a method and reference system for measuring the hardness of materials such as rubber and plastic with a tool called a durometer. The exact . A hardness test uses a limited compressive force to apply a small deformation to the surface of a material, in order to assign a relative value for the material’s hardness. However, a ductility test uses a destructive tensile force .

The hardness of a polymer is an empirical quantity related to the inherent indentation resistance. The two most common methods for measuring polymer hardness are the Rockwell hardness test [18] and the Shore (durometer) hardness test [19]. These tests provide a fast and easy method to characterize the hardness of a polymer.

Abstract. The Durometer hardness test is one of the most commonly used measurements to qualitatively assess and compare the mechanical behavior of elastomeric and elastomeric-like materials. This paper presents nonlinear finite element simulations of hardness tests which act to provide a mapping of measured Durometer Shore A and D values to the . The durometer hardness test results are reported in either Shore A or Shore D scales, depending on the type of material being tested. The Shore A scale is used for softer materials, while the Shore D scale is used for harder materials. The Shore A scale ranges from 0 to 100, with 0 being the softest and 100 being the hardest. .The Shore D Hardness test is also called Durometer Hardness Test. The letter "D" symbolizes the type of durometer used to measure the hardness of a material. It is a dimensionless quantity. It goes between 0 and 100. The higher number of hardness represents the harder material.

shore a vs d durometer

USA Testing Lab for ASTM D2240 Standard Test Method for Rubber Property-Durometer Hardness in USA, Indonesia, Philippines, Malaysia, Thailand, Canada, China, India, and all over the World. (302)244-7710 . . ASTM D2240 Standard Test Method for Rubber Property-Durometer Hardness. ASTM D2240 encompasses twelve types of rubber hardness . Figure 1: Durometer Schematic Surface Hardness Indicator A durometer gage measures the depth of surface penetration for a pin of a . Degrees (IRHD) and durometer are used interchangeably, since the test methods and theory are basically the same. Note, however, that durometer and IRHD will not necessarily be numerically equal. The geometry of the indentor and the applied force influence the measurements such that no simple relationship exists between the measurements obtained with one type of durometer and those obtained with another type of durometer or other instruments used for measuring hardness. This test method is an empirical test intended primarily for .Automatic Shore IRHD Hardness Tester Durometer designed for precision, efficiency, and user-friendly operation, this instrument comes up with a versatile features such as interchangeable measuring heads, motor-controlled displacement, and automatic specimen rotation. With compatibility on standard PCs running Windows 10 or 11, USB connectivity, and seamless .

Test Shore hardness of rubber and plastics. A Durometer is a material hardness tester for rubber, elastomer, plastic and other similar compounds. They use a specific spring force and indenter shape combination to measure the indentation depth created and the corresponding resistance, according to the ASTM D2240 test standard.

The Durometer hardness test is one of the most commonly used measurements to qualitatively assess and compare the mechanical behavior of elastomeric and elastomeric-like materials.The hardness of plastics is most commonly measured by the Shore® (Durometer) test or Rockwell hardness test. Both methods measure the resistance of plastics toward indentation and provide an empirical hardness value that doesn't necessarily correlate well to other properties or fundamental characteristics.

Digital Shore Durometer – Shore Hardness Tester– DRIVE Series Key Features: Highest Accuracy and Repeatability: High-resolution sensor and frictionless mechanical construction ensure precise and repeatable measurements. Comprehensive Data: Calculate initial and post-test hardness, measure ambient temperature, specimen surface temperature, and relative .How the test works Shore hardness (also known as 'Durometer hardness') is determined by measuring the penetration of the Durometer's spring loaded indenter into the sample. The operator applies the instrument to the sample with sufficient contact force, in a consistent manner and without shock. During application the indentationThe Durometer is a popular instrument for measuring the indentation hardness of rubber and rubber-like materials. The most popular testers are the Model A used for measuring softer materials and the Model D for harder materials. To perform a Shore durometer hardness test, the device is loaded with an indenter. The indenter is then forced onto a material using a spring that applies a known force. The indentation on the material is then measured. Durometer hardness measurements are conveyed as a number on the Shore scale. There are several types of Shore scales that can .

How Do You Measure Shore Hardness. The Shore Scale was created by Albert Shore back in the 1920s. He was a metallurgist and is credited as the founder of the durometer, which is the instrument used to measure . Abstract. Polymer durometry is the measurement of the hardness of plastic and rubber materials using an indentor. Many different hardness scales and indentor geometries have been standardized for durometry. Indentation into a solid is governed by linear elastic mechanics, and this paper relates the Young’s modulus to standardized hardness scale reading. We .

ASTM D2240 durometers allow for a measurement of the initial hardness, or the indentation hardness after a given period of time. The basic test requires applying the force in a consistent manner, without shock, and measuring the hardness (depth of the indentation). If a timed hardness is desired, force is applied for the required time and then .Durometer Hardness is used to determine the relative hardness of soft materials, usually plastic or rubber. The test measures the penetration of a specified indentor into the material under specified conditions of force and time. The hardness value is often used to identify or specify a particular hardness of elastomers or as a quality control . The Shore hardness scale that should be used depends on the test specimen material, while the shape and size of the indenting foot depend on the Shore hardness scale. Lay the test specimen on a hard, flat surface that is ¼” thick or greater. Test the Shore hardness of the material by placing the durometer and its indenting foot against the . Whether you need to test the hardness of metal, plastics, or ceramics, Starrett Hardness Testers are an essential tool for quality control and materials testing in a variety of industries, including manufacturing, aerospace, and automotive. Browse through our diverse product offering. Read through the reference information provided.

Durometers may be used to test the hardness for any material. However, these tools are more commonly used when working with rubber or plastic. Background of Durometer Standardization. In the 1920, Albert Ferdinand Shore developed a tool to measure material hardness, known as the Shore durometer. Today the Shore durometer is still used and .F1957 Test Method for Composite Foam Hardness-Durometer Hardness 2.2 ISO Standard: 3 ISO/IEC 17025: 1999 General Requirements for the Com-petence of Testing and Calibration Laboratories 3. Summary of Test Method 3.1 This test method permits hardness measurements based on either initial indentation or indentation after a speciÞed period of time .Durometer /Shore hardness Tester. Durometer are used for determining the material hardness of rubber, plastic and other rubber like substance such as neoprene, silicone, vinyl, also be used for soft plastics, felt, leather and similar materials. Shore hardness value in the range from 0 to 100. Maximum penetration for each scale is 2.5 mm.A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

This Type D durometer tests the hardness of hard rubber and plastics. Test block for Type D durometers provides you the ability to develop the proper "feel". while not to be used for calibration purposes, this Test block enables you to perform a quick check for the proper operation of the durometer.

Resultado da condor,英语单词,主要用作名词,作名词时译为“(Condor)人名;(法、西、罗)孔多尔”。

durometer hardness test theory|durometer hardness tester